Adelco

DTF Printer

DTF Printer

Couldn't load pickup availability

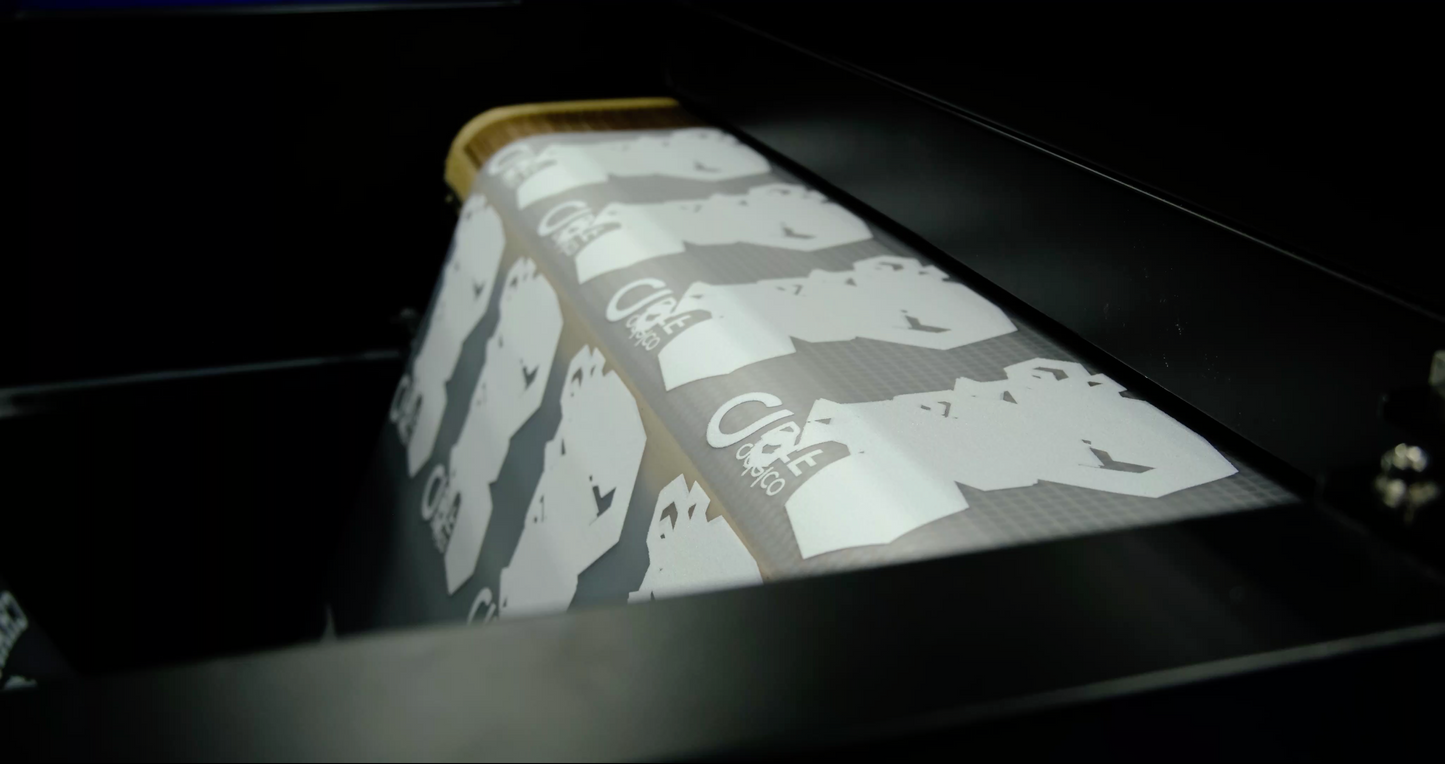

Offering the most complete DTF portfolio. From desk top entry level to the fastest and highest spec printers in the market. Optional inline cutters are available for 2H, 4H and 8H printers making it the most complete solution in the market.

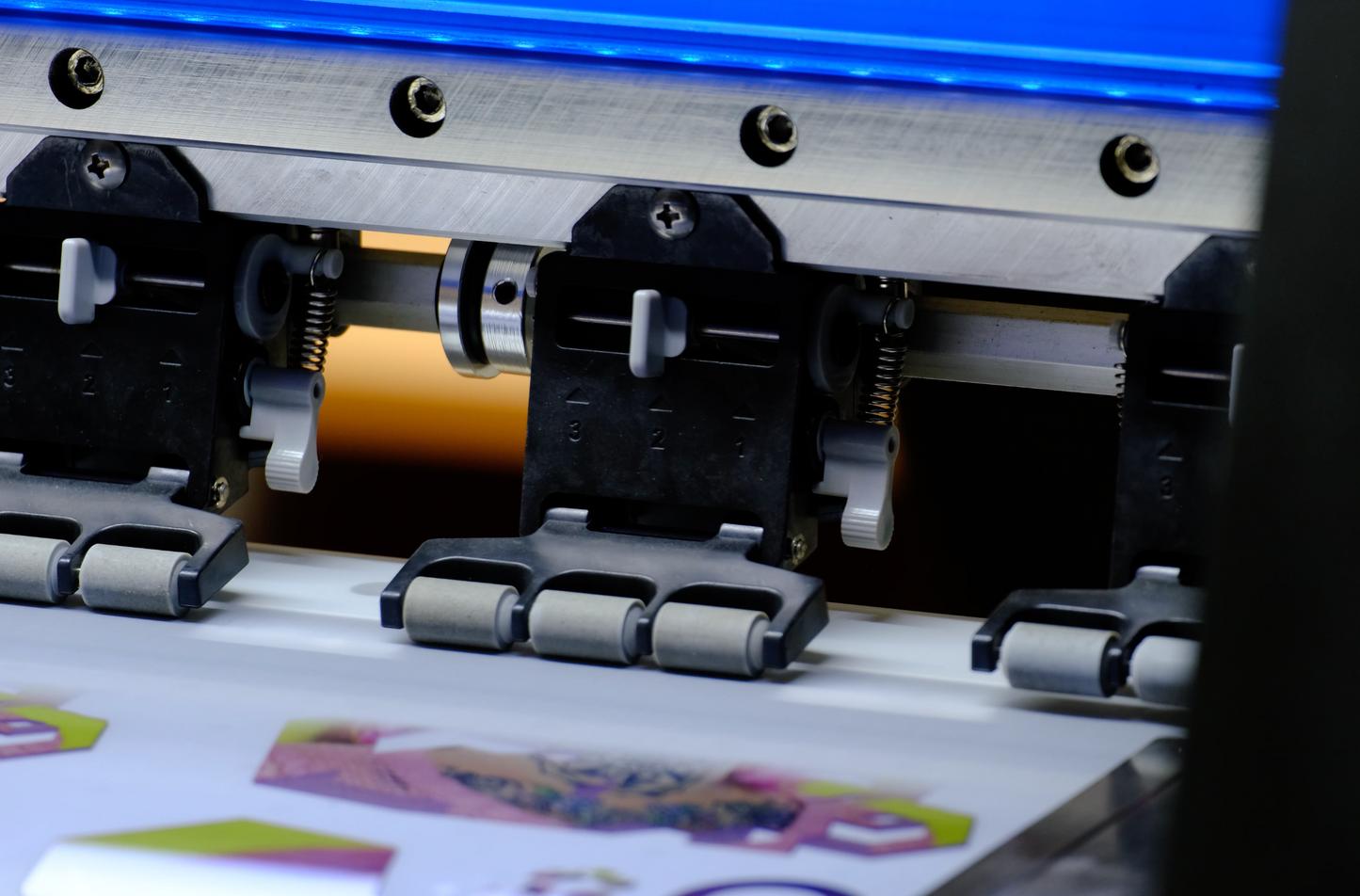

Adelco’s Direct to Film printers have a high aluminum milling frame ensuring a stable output with two, four or eight print heads. These solutions come with an advanced mechanical control system that ensures more stable printing. With a thoughtful and easy touch screen operating system the printer is easy to use. Features of the printer includes:

- A precision paper pinch roller - Ensures accuracy and stability of the paper.

- Advanced capping station - Keeps ink flow fluent.

- Intelligent system with suction panels - Simple and responsive.

- Ink alarm system - allows ink to be added in advance, avoiding printing abnormalities caused by ink shortage.

- Anti-collision system for print heads - avoid collision between print head and trolly.

- Industrial motor drive - High spec, improved printing efficiency.

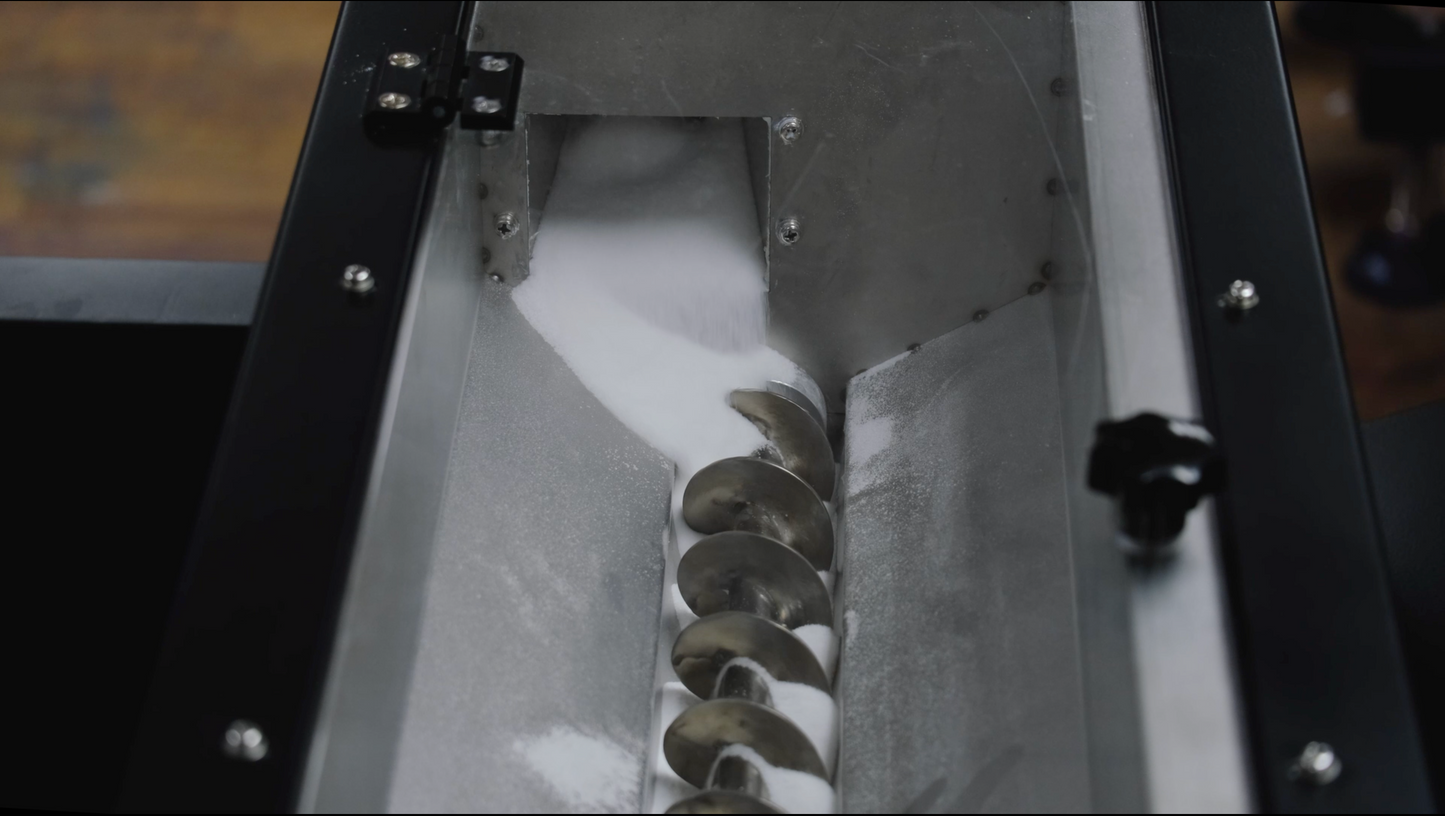

Adelco’s DTF models come complete with automatic re-circulating powder unit, making the process efficient and seamless. Features include:

- Drying system - ensuring immediate drying when printing at speed.

- One meter heating tunnel - Progressive heating with long service life, even and economical heating.

- Built-in cooling unit - Automatically controls and adjusts the temperature.

- Touch screen control system - Intelligent digital control simple and effective.

- High performance paper feeding device. - suitable for a variety of materials.

These prices do not include shipping and installation.

Specifications

| 2 Head DTF | 4 Head DTF | 8 Head DTF | |

| Printing Heads |

2 x Epson I3200 - A1 |

4 x Epson I3200 - A1 |

8 x Epson I3200 - A1 |

| Print Width |

600mm |

600mm |

1200mm |

| Resolution |

3200dpi |

3200dpi |

3200dpi |

| Colour |

CMYK & White |

CMYK & White |

CMYK & White |

|

Ink Type |

Pigment Ink |

Pigment Ink |

Pigment Ink |

|

Power Supply |

220V - 50HZ/60HZ (110V Option) |

220V - 50HZ/60HZ (110V Option) |

220V - 50HZ/60HZ |

|

Power |

1400W |

1500W |

2200W |

|

Speed |

4 pass: 14m2/h 6 pass: 11m2/h 8 pass: 8m2/h |

4 pass: 27m2/h 6 pass: 17m2/h 8 pass: 13m2/h |

4 pass: 55m2/h 6 pass: 36m2/h 8 pass: 27m2/h |

|

Operation Environment |

Temperature 18 - 35°C, Humidity: 40RH - 70RH |

Temperature 18 - 35°C, Humidity: 40RH - 70RH |

Temperature 15 - 30°C, Humidity: 40RH - 70RH |

|

Machine Size |

1680 x 820 x 1430mm |

1925 x 800 x 1667mm |

- |

|

Package Size |

2370 x 750 x 650 mm |

2300 x 760 x 860 mm |

2930 x 910 x 900 mm |

|

Weight |

160Kg |

216Kg |

386Kg |

|

Re-Circulation Powder System |

Yes |

Yes |

Yes |

|

Applicable Film Width |

600mm |

600mm |

1200mm |

|

Applicable Speed |

14m2/h |

27m2/h |

55m2/h |

|

Platform Temperature |

75°C |

75°C |

75°C |

|

Drying Temperature |

110°C |

110°C |

110°C |

|

Media Type |

PET transfer film |

PET transfer film |

PET transfer film |

|

Media Transport |

Belt guide system and dual powered take-up |

Belt guide system and dual powered take-up |

Belt guide system and dual powered take-up |

|

Power Supply |

220V 50HZ/60HZ |

220V 50HZ/60HZ |

220V 50HZ/60HZ |

|

Supply |

5000W |

6500W |

12000W |

|

Operation Environment |

Temperature 18-30°C Humidity 40Rh-60RH |

Temperature 18-30°C Humidity 40Rh-60RH |

Temperature 18-30°C Humidity 40Rh-60RH |

|

Heating |

Intelligent 5 heating tubes infrared heating |

Intelligent 10 heating tubes infrared heating |

10pcs x 805mm (800W/pcs) |

|

Machine Size - Shaker |

1920 x 1000 x 1210mm |

3122 x 1130 x 1105mm |

3210 x 1510 x 1320mm |

|

Package size - Shaker |

1850 x 1150 x 1280 mm |

2360 x 1150 x 1280 mm |

2360 x 1790 x 1280 mm |

|

Weight - Shaker |

270Kg |

297Kg |

590Kg |

Share